Manufacturing

- Categories:Manufacturing

- Time of issue:2021-08-19 17:02:15

- Views:0

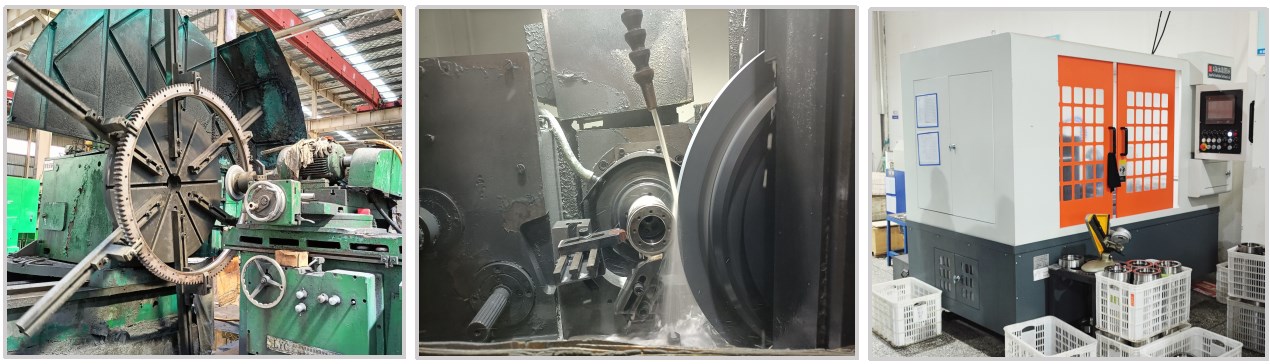

1. Turning

-

Rough turning.

-

After rough turning, the workpiece is detected by an ultrasonic flaw detector to examine cracks or other flaws and ensure the bearing’s stable quality and normal service life.

-

Quenching and tempering can be conducted according to the requirements, to improve the strength and fatigue resistance of the material.

-

Aging treatment (within 48h) is carried out to eliminate the inner stress and prevent workpiece deformation.

-

Finish turning. In this process, in order to prevent the bearing parts deformation, the parts clamping tool must be loosened first and retightened again after adjustment.

-

Special process for inner rings of crossed roller bearings and three-row roller slewing bearings: the inner rings of these bearings must be processed in pair and cut after heat treatment.

t treatment

2. Heat treatment

- Perform medium frequency hardening on the surface of bearing raceway to form a hardened layer with hardness≥55HRC, depth≥4mm and the width of soft zone is≤50mm with a “S” mark on it.

- Perform dye penetrant inspection to detect whether there are cracks or other flaws on the raceway.

3. Gear Processing

For bearings with external or internal gear, gear processing should be performed prior to grinding process to achieve the required gear accuracy.

4. Drilling

rogram on the CNC drilling machine according to the drawing and verify the size accuracy prior to drilling holes. Slewing rings with split inner/outer ring should be processed in combination to control the hole distance deviation within 0.5mm.

5. Grinding

- Rough grinding: the 36 grit resin wheel is used and the grinding speed should be≤1500 rpm to prevent raceway damage and the grinding depth should be≤1mm.

- Fine grinding: 46 or 60 grit resin grinding wheel is used to finely process the slewing bearings and achieve the required surface finish and size accuracy.

6. Assembly

- After grinding, pre-assembly is carried out to calculate and adjust the clearance.

- After adjusting the clearance, check the start friction torque. If it is not acceptable, adjusting the race way and clearance again to achieve the required value.

7. Inspection

Parts inspection: cleaning the bearing parts, perform the final inspection and document the results.

8. Packaging & Shipping

The qualified products are cleaned, greased, packaged, crated, and shipped to the customer with related certifications.

Contact Us

TEL: +86-379-68777181

PHO: +86-159-3792-4313

FAX:+86-379-64861689

EMAIL:export@jw-bearing.com

ADD:Yiyang Industry Gathering Zone,Luoyang City, China

Copyright © Luoyang Jiawei Bearing Manufacturing Co., Ltd.

Powered by www.300.cn This website supports IPV6 access